颜料红 175

pigment red 175

CAS: 6985-92-8

Molecular Formula: C26H19N5O5

颜料红 175 - Names and Identifiers

颜料红 175 - Physico-chemical Properties

| Molecular Formula | C26H19N5O5 |

| Molar Mass | 481.46 |

| Density | 1.47±0.1 g/cm3(Predicted) |

| Boling Point | 605.0±55.0 °C(Predicted) |

| Flash Point | 319.7°C |

| Vapor Presure | 3.11E-15mmHg at 25°C |

| pKa | 11.41±0.30(Predicted) |

| Refractive Index | 1.724 |

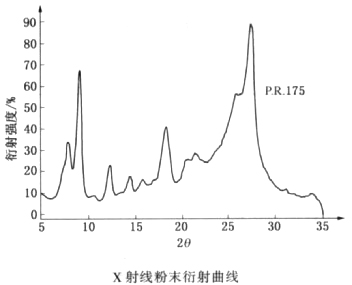

| Physical and Chemical Properties | hue or color: yellow, red density/(g/cm3):1.48 Bulk density/(lb/gal):11.6-12.6 melting point/℃:340 average particle size/μm:100 particle shape: Rod specific surface area/(m2/g):5;62 pH value/(10% slurry):6.5 oil absorption/(g/100g):65-70 hiding power: transparent diffraction curve:  reflection curve:  red to blue-red. Good light resistance. Heat resistance up to 200 °c. The stability of ethanol, ether, acetone, xylene was 4~5. |

| Use | The pigment is in dark Red color with a hue angle of 28.5 degrees (1/3SD); The product is transparent with high specific surface area, and the specific surface area of PV Fast Red HFT is 56 m2/g; good fastness properties; Mainly used in coatings and plastics, automotive coatings (OEM), no bleeding resistant to finishing paint, heat-resistant 200 ℃; In the soft plastic and hard PVC light fastness to climate fastness 7-8, brown with carbon black; Resistant to migration in soft PVC; In HDPE (1/3SD) heat resistance of 270 C/5min, the size of the deformation is not obvious; Also used for polypropylene pulp coloring. can be used for coloring of paint, polyethylene and polystyrene. Polyvinyl chloride. |

颜料红 175 - Reference Information

| EPA chemical substance information | information provided by: ofmpeb.epa.gov (external link) |

| Application | can be used for coloring of paint, polyethylene and polystyrene. Polyvinyl chloride. |

| production method | reaction equation operation procedure 7.6 parts (purity 99%) of methyl anthranilate, 100 parts of 2mol/L hydrochloric acid and 100 parts of water were dissolved by stirring and cooled to 6 °c. With rapid stirring, 25 parts of a 2mol/L sodium nitrite solution were added once, and the reaction became transparent. After stirring for 1H and filtering, the filtrate was destroyed with excess nitrous acid by using a solution of sulfamic acid, and 60 parts of 2mol/L sodium acetate was added thereto, so that the pH of the solution was 5. 19 parts (84%) of 5-(2 '-hydroxy-3'-benzamido)-benzimidazol-2-one, 75 parts of 2mol/L sodium hydroxide solution and 300 parts of water were heated to 50-60 °c with stirring, insoluble matters were removed by hot filtration, and the filtrate was cooled to room temperature. Drop the solution to the above diazo solution within 2H at 10 ℃ or less, control pH = 5~6.2, stir for 1H after coupling, heat to boiling, hot filtration hot water wash to neutral, dried to give 23 parts of crude pigment. The finely ground pigment was added to 230 parts of dimethylformamide, heated to 140-145 °c with good stirring, maintained for 2H, cooled to 100 °c, filtered, and washed with water to give 21.5 parts of red pigment. |

Last Update:2024-04-09 21:04:16